Transforming your

manual machine for automation.

- Simple automation of your lathe and milling machine

- Flexible to fit your existing machine.

- Customised to suit your needs.

- No robot programming knowledge required

- No downtime when filling the ROBOBOX

VIDEO: The ROBOBOX in ACTION

THE SIMPLE SOLUTION

for small and medium-sized companies.

Perfect, cost-effective entry into robot integration to automate your existing lathe and/or milling machine.

This makes you even more flexible for your small series and batch sizes.

Thanks to the new possibility of unmanned, autonomous production, it is now possible to produce at night and increase cycle times.

A space-saving, universal robot cell to further advance your lean management.

Automation makes your company more attractive to customers and employees.

-

Enter the world of automation

To ensure you remain competitive where your company is based.

-

Space-saving

Cost-effective automated production of small batches

-

Unmanned

Production, with no need for you to be on hand.

-

Customisable!

So it meets your exact requirements.

NOW IT’S YOUR TURN!

Configure your ROBOBOX!

Configure automation individually for your needs here:

What our customers say:

The ROBOBOX is running really well and we are putting it to very good use. We are very happy with how our collaboration with SPINNER automation is going, and that all communication and work takes place on an equal footing.

Firma Desaga

Mr. Kirchner

but why?

What specific support does the ROBOBOX provide?

24-hour production

Production can take place without any staff during night and late shifts.

Use of personnel resources

Your employees’ creativity and skills can be used for other tasks.

In the event of staff shortages

The ROBOBOX helps to eliminate staffing bottlenecks.

Unmanned

More machine hours without more staff.

Why is automation important?

-

To safeguard your business location

Over the medium term, this will be the only way to manufacture products economically in Germany/Europe.

-

To remain competitive

Cost-effective automated production of small batches.

-

External perception

Appealing in the eyes of customers and personnel.

-

Skilled labor shortage

You need fewer skilled workers (+they can be better deployed)

-

Capacities

You can produce more parts (24-hour capacity)

-

Cost reduction

Automation is more cost-effective in the long term

-

Save on personnel

You generally need far fewer personnel

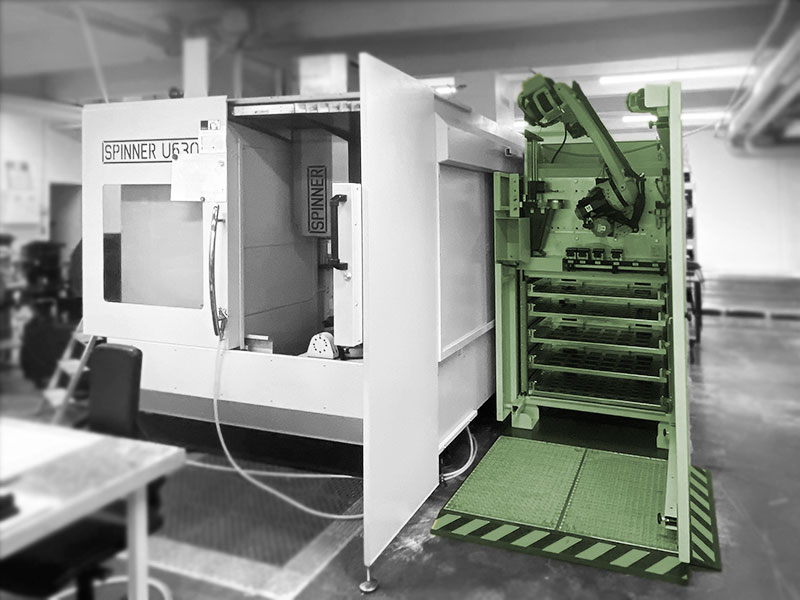

Connecting the ROBOBOX

Examples of how the ROBOBOX can be connected to SPINNER machines:

ROBOBOX on the VC850

MAXIMUM BENEFIT IN

A VERY SMALL AREA

ROBOBOX on the U5

AUTOMATED PRODUCTION OF 5 AXIS PARTS,

EVEN WITH SMALL BATCH SIZES

ROBOBOX on the TC400

CHUCK PARTS FITTED

AUTOMATICALLY

ROBOBOX on the TC600

PRODUCE INTEGRATED PARTS IN A FULLY

AUTOMATED PROCESS OR OFF THE RACK

Do you have a specific project in mind?

ROBOBOX around the world.

The Robobox is already hard at work at these locations:

At a Glance

All the benefits of the ROBOBOX

Easy

Production can take place without any staff during night and late shifts.

Manageable costs

Manageable investment with great benefits for your future

Easy to get started

An easy way to enter the world of automation

Perfected for Spinner machines

Prepared to perfection for Spinner machines. When it comes to other manufacturers, we are as good as anyone else

Further training for your employees

Personalised training: We will pick your people up wherever they are. Acquire new expertise at your own site.

Simple programming

The programs are simply created by entering a few values.

No downtime

When loading the ROBOBOX, the robot can continue working in parallel. This means that we do not have any machine downtime.

Space-saving

We rely on a compact design and modern sensor technology that only requires a minimum of space, but optimally covers all the required safety features.

We don’t build anything “off the rack” for you.

Configure your ROBOBOX according to your requirements!

Customised for you!

Using our standard basic frame as a foundation, we work with you to adapt the ROBOBOX to the individual requirements of your components.

Made to measure!

It is possible to customise individual options in the ROBOBOX configurator - but we would also be happy to look at requirements beyond this with you.

Configure your very own ROBOBOX using our configurator:

New technology

that is easy to understand:

So easy to learn!

New technology - easy to understand.

Space-saving

2.9 m² of space can be found in almost any hall.

Easy to get started

An easy way to enter the world of automation

Storage capacity

1.8 tonnes is available across 9 drawers for components.

Fast

No time lost on time-consuming set-up of the automation thanks to simple adjustment features.

VIDEO The ROBOBOX in ACTION

Got a specific project in mind and want to get started right away?

We look forward to receiving your enquiry!

Jörn Maier

ADVICE

Telefon: +49 71 45 / 9 35 08 – 31

Dominik Jauch

ADVICE

Telefon: +49 71 45 / 935 08 – 10

Well then!

You work from back to front and

like to ride your bike backwards?

Then our

ROBOBOXtreme.

is the right choice for you.ROBOBOXtreme means: breaking the mould!

ROBOBOXtreme means:

breaking the mould!

First step:

The robot picks up a clamping device from the store, positions the clamping jaws, uses them to clamp a component from the drawer and transfers the clamping device with component to the machine.

Second step:

The robot tells the machine which machining program belongs to the component, and the machine can start working.

This sounds like manual production if the word ROBOT is replaced by HUMAN.

But it is the ideal solution for automating the production of individual parts and small batches.

All of this is possible with the ROBOBOXtreme.

Got any questions?

We would be happy to assist you!

Jörn Maier

ADVICE

Telefon: +49 71 45 / 9 35 08 – 31

Dominik Jauch

ADVICE

Telefon: +49 71 45 / 935 08 – 10

Adress:

Contact:

Tel.: +49 (0)7145 93 508 – 0

Fax: +49 (0)7145 93 508 – 55

E-Mail: info@spinner-automation.de